The coolest things about these awesome machines is that they actually work pretty fast & accurate. They can produce pipes more quickly than previously and ensure that each one is precisely tailored. This enables companies to manufacture substantial quantities of pipes within a short period, allowing them to accomplish more work faster.

And these machines also use novel methods to create various types of pipes. They are able to make pipes in all kinds of shapes and sizes. This provides companies with the opportunity to produce pipes that they were unable to produce previously. They can even adjust the internal piping to customize it for their customers.

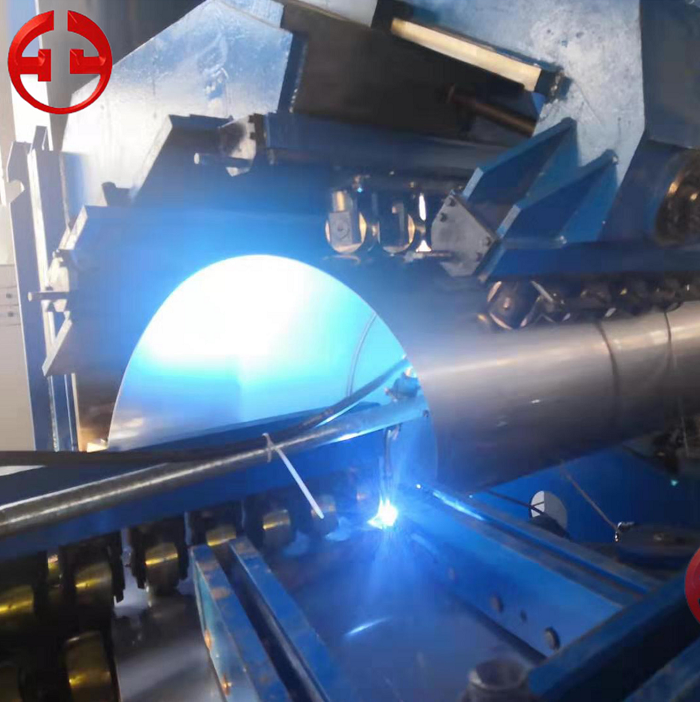

Another way these machines Spiral Pipe Mill assist is by doing a lot of work alone. That means workers do not have to do everything manually. This allows pipes to be produced quicker and with lesser error. Once they have some data, businesses can use machines to improve pipe quality more reliably.

These processes also allow these machines the unique ability to create pipes from a wide range of materials, including steel, aluminum, and copper. This is useful for building pipes of many spiral pipe mill kinds for companies. They can craft thick or thin pipes, short or long, to suit what customers require.

Finally, these machines allow companies to stay in sync with what people want in the present day. They can produce pipes quickly and cost-effectively. In this manner, organizations can offer quality pipes without incurring much financial cost. The new technology allows them to rapidly shift their production to meet new demand.

In conclusion, the spiral pipe mill technology provides variety of advantages that alter the traditional spiral pipe machine procedures for pipe manufacturing. In their speed, accuracy and novel methods of working, these machines are better equipping companies to meet the needs of the moment. This technology allows companies to continue doing what they do best, which is manufacturing quality pipes for an ever-growing variety of applications.